Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-02-12 Origin: Site

1. Basic concepts and importance of the tolerance chain

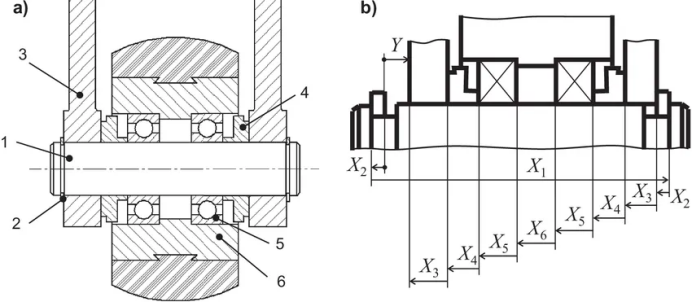

A tolerance chain is a precision chain consisting of the tolerances of multiple components. During mechanical assembly, the tolerance error of any part will affect the overall assembly accuracy. Specifically, the tolerance chain is transmitted through the size error of each component, and ultimately affects the accuracy of the assembly. Reasonable control of the tolerance chain design, help to reduce the accumulation of errors, so as to ensure the performance and service life of the overall equipment.

For example, in complex mechanical equipment, the coordination error of gears, bearings, connecting parts, etc., may be continuously transmitted through the tolerance chain, leading to the continuous amplification of the assembly error. Therefore, the effective calculation and optimization of the tolerance chain can improve the accuracy of the overall assembly and reduce the production cost and the rate of the products.

2. Calculation method of the tolerance chain

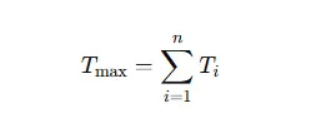

2.1 Maximum tolerance method

Maximum tolerance method is the most traditional tolerance chain calculation method, which obtains the maximum tolerance of the assembly by summing the tolerance value of each component. This method is simple and intuitive, and it is suitable for the design of high-precision requirements.

formula:

Where, Ti is the tolerance for each component.Although conservative, this method ensures that the tolerance error in the assembly process does not exceed the allowable range.

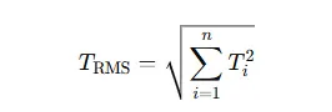

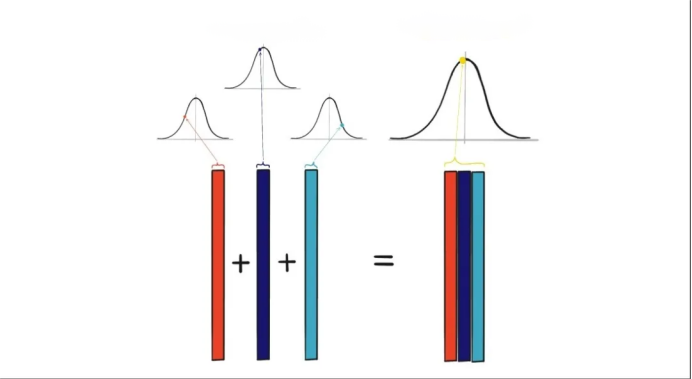

2.2 Root mean square method (RMS method)

The root mean square method (RMS) considers the random distribution of tolerance error, and uses the sum of square square to calculate the error of tolerance chain, which can provide a more reasonable estimate.

formula:

This method is suitable when the error distribution is relatively uniform and can more accurately reflect the influence of error transmission between components.

2.3 Simulation and analysis method

In modern mechanical design, simulation analysis simulates the actual coordination state of each component by using computer-aided design (CAD) and finite element analysis (FEA) tools. Through extensive simulation analysis, the tolerance design can be discovered and optimized in advance.

3. Optimization design method of tolerance chain

3.1 Optimize the tolerance distribution

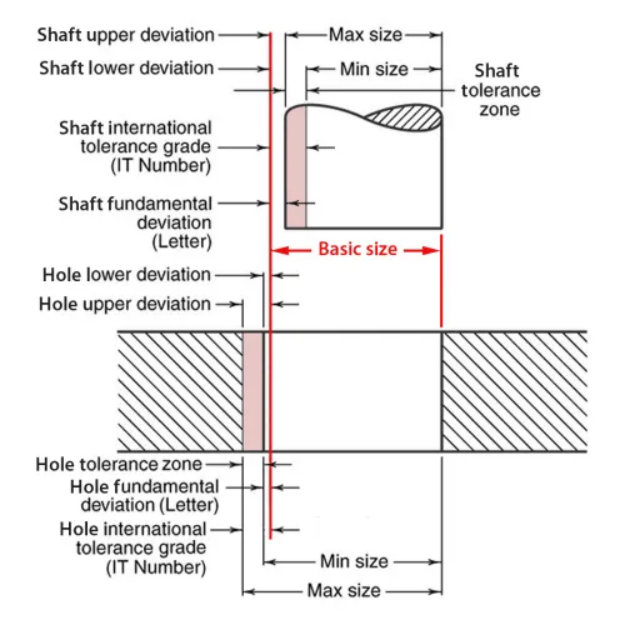

The optimization of the tolerance chain should first consider how to reasonably allocate the tolerance to each part, and avoid excessive error concentrated on a single part. Common optimization strategies include:

Priority control of key components for the most critical parts affecting the assembly accuracy, such as bearing seat, gear, etc., to adopt stricter tolerance requirements.

For components with low accuracy requirements, the tolerance can be appropriately relaxed to reduce production costs.3. Optimization design method of tolerance chain

3.1 Optimize the tolerance distribution

The optimization of the tolerance chain should first consider how to reasonably allocate the tolerance to each part, and avoid excessive error concentrated on a single part. Common optimization strategies include:

Priority control of key components for the most critical parts affecting the assembly accuracy, such as bearing seat, gear, etc., to adopt stricter tolerance requirements.

For components with low accuracy requirements, the tolerance can be appropriately relaxed to reduce production costs.

3. Optimization design method of tolerance chain

3.1 Optimize the tolerance distribution

The optimization of the tolerance chain should first consider how to reasonably allocate the tolerance to each part, and avoid excessive error concentrated on a single part. Common optimization strategies include:

Priority control of key components for the most critical parts affecting the assembly accuracy, such as bearing seat, gear, etc., to adopt stricter tolerance requirements.

For components with low accuracy requirements, the tolerance can be appropriately relaxed to reduce production costs.

3. Optimization design method of tolerance chain

3.1 Optimize the tolerance distribution

The optimization of the tolerance chain should first consider how to reasonably allocate the tolerance to each part, and avoid excessive error concentrated on a single part. Common optimization strategies include:

Priority control of key components for the most critical parts affecting the assembly accuracy, such as bearing seat, gear, etc., to adopt stricter tolerance requirements.

For components with low accuracy requirements, the tolerance can be appropriately relaxed to reduce production costs.